Download Catalogue for CLC Block Cutting Machine - MiniCutter

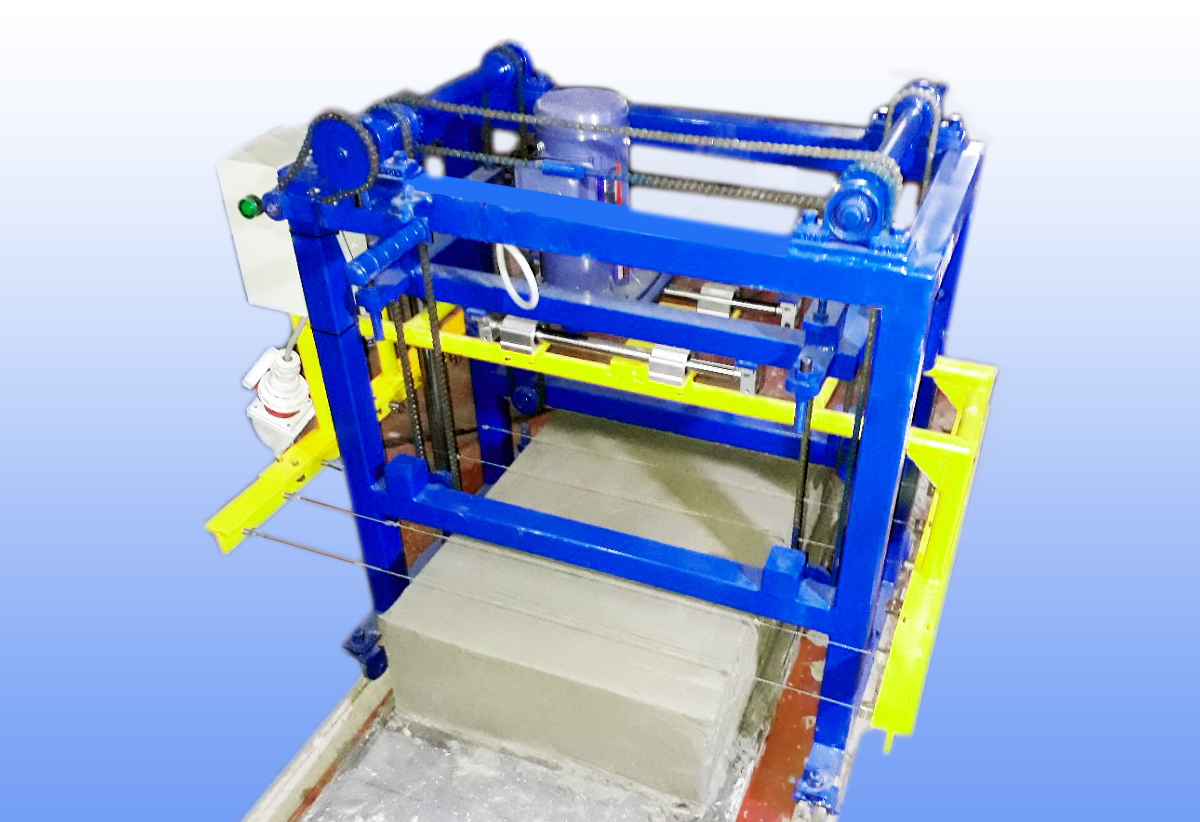

Small & compact CLC block cutting machine - MiniCutter

Compact foam concrete cutting machine - MiniCutter made in Vietnam by THT International Co., Ltd.

This mini CLC block cutting machine uses steel cutting wires to cut the foam concrete cakes cast into blocks of different sizes.

It helps the small producers who usually use battery molds to eliminate the blocks partition wall plates inserted into the molds and greatly increase efficiency and reduce costs.

By using this small CLC block making machine, the production capacity will become higher, the quality of blocks will be greatly improved and the production cost will be much-reduced thanks to the savings on labor and material costs.

Advantages of our foam concrete cutting machine

Foam concrete cutting machine in plant

Foam concrete cutting machine is making clc blocks

CLC block cutting machine use wire to cut the blocks

Small & Compact

MiniCutter is the world’s smallest CLC block cutting machine, with durable cutting wires, and compact steel frame.

Easy to Operate

MiniCutter can be easily operated by anyone, at any job site thanks to the smart wheeled and wire-cutting system

Costs Saving

With MiniCutter, you no longer need battery moulds to produce high quality bricks, and can save on production and labour costs

CLC block cutting machine and worker work in plant

CLC blocks after cutting by MiniCutter

CLC block cutting machine - MiniCutter

Technical specifications

|

Electric power |

0.25kW/380V/50Hz |

|

Capacity |

from 5 to 7m3/shift (with electric gear motor) |

|

Mobility |

The machine has 4 wheels for manual travel along the mould lines, with manual brakes for stabilizing the machine during the cutting action |

|

Operating modes |

Can be operated in 2 modes: electrically driven mode by a small electric motor and manual mode in case of a power outage. The manual mode will allow a continuous production process, to avoid the need of a electric generator |

|

Cutting Wires |

With 6 cutting wires tensioned by bolts, moving back and forth along 2 high-quality chrome plated shafts with 4 special linear bearings which gives a very easy and smooth movement of the cutting frame |

|

Cutting frame |

Cutting frame can move downward freely on 2 vertical stainless steel shafts guided by 2 bushings to create the pressing force of cutting wires on the CLC cakes. The rise of cutting frame after each cutting action is made manually by a rotating handle. |

|

Cutting speed |

One cutting action takes around 10-20 seconds maximum. The machine can start cutting in 3-4 hrs after pouring. |

|

Block size |

Can cut a long cake of 500/600(W) x 200(H) x 2400(L)mm into 24 blocks of 100x200x500/600mm. Other blocks size possible by changing the distance between the cutting wires. Cake can be longer than 2400mm if the length of the molded panel is longer. |

|

Weight |

65kgs |

| Mould size |

600(R) x 1000 (D) x 850mm (C) |

Video demo of MiniCutter - World's smallest CLC wire cutting machine

Mobile machine with 4 wheels for manual travel along the mould lines, with manual brakes for stabilizing the machine during the cutting action.

With 6 cutting wires tensioned by bolts, oscillating back and forwards along 2 high quality chrome plated shafts with 4 special linear bearings which gives a very easy and smooth movement of the cutting frame. Cutting frame can move downward freely on 2 vertical stainless steel shafts guided by 2 bushings to create the pressing force of cutting wires on the CLC cakes.

This Foam concrete cutting machine can cut a long cake of 500/600(W) x 200(H) x 2400(L)mm into 24 blocks of 100 x 200 x 500/600mm in 10-15min.

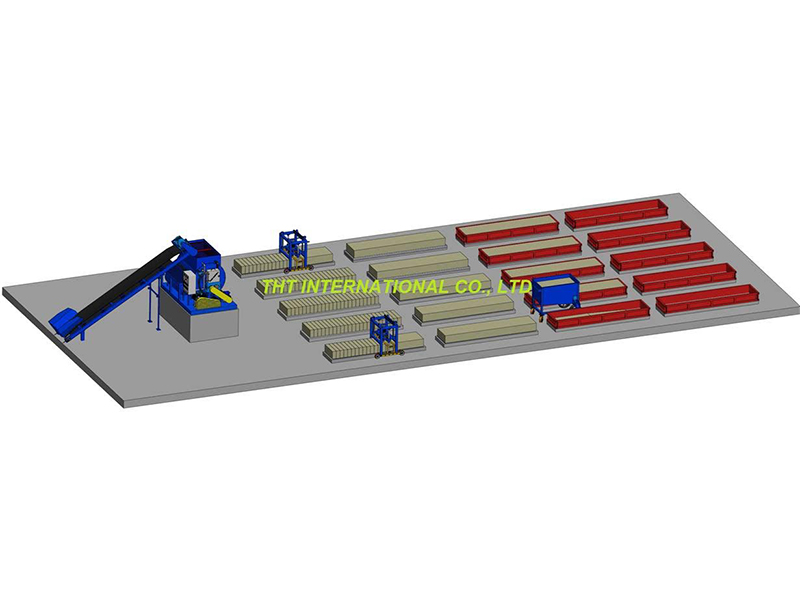

MiniCutter in Small CLC block production plant

Our MiniCutter cutting machine is designed to be part of a mini CLC block manufacturing plant.

A mini CLC blocks production line of 10-15m3 per day can be designed as per the below illustration with one mixer with capacity of 0.5m3, a pouring cart, several molds and one or 2 MiniCutter machines. This type of plant is very suitable for the rural area or developing countries where electricity may not be stable and labor is plentiful and cheap.

The production process:

- Lightweight concrete is mixed in a mixer (containing air compressor, foam generator and control cabinet). Then, it is poured into mold 2400 x 500x 200mm.

- After about 3 hours, use MiniCutter to cut a long concrete cake into blocks of 100x200x500 mm.

- Bricks are cured by spraying water outside the storing area. After 3 weeks, it can be supplied to the construction site.

Mini CLC block production line

Other relevant CLC block making machines

We have also supplied many kinds of CLC block making machines since 1996.

Cellular Lightweight Concrete Technology

We are one of the leading manufacturers of CLC foam concrete equipments, and have exported to many countries around the world. We can supply machines as part of a production line, or complete turn-key manufacturing plants.

Lightweight Concrete Equipments