Large CLC Blocks plant technical information

CLC block plant - High capacity and fully automatic Aircrete plant

We are one of the leading Aircrete plant manufacturers, and we can design and install plant for CLC bricks with capacity from 20m3 to 300m3/day.

The plant will be designed with different configurations to meet the various requirements of our clients, from required daily capacity, available land/factory, size of initial investments, to the type of materials used in the concrete.

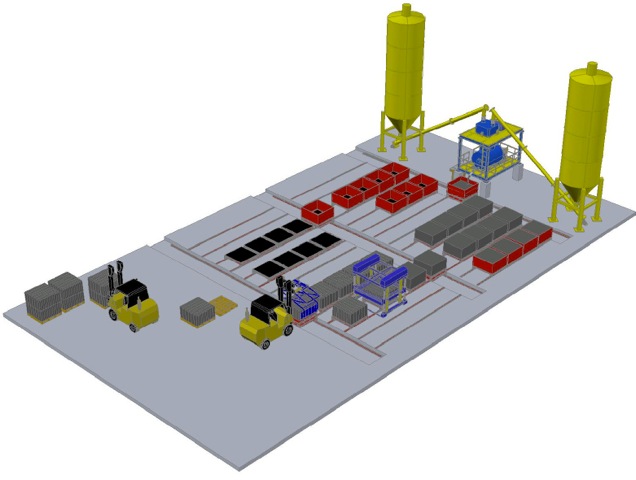

Layout design of a simple CLC Block plant with capacity of 200m3/day

High quality

Our plant consists of high quality equipments, with components from well-known manufacturer such as Schneider, LG, Omron... to ensure long product life cycle.

Modular design

With our cleverly designed modular system, you can easily decrease/increase the capacity of your plan just by increasing the number of moulds and cutting machine.

Flexibility

We can design your plan with different level of automation to suit your needs and budget, and ultimately help you to save costs in the long run

Materials required to produce CLC blocks

To make 1m3 brick having the density of 850kg/m3 with this CLC block plant, materials required are:

- Portland cement: 330 - 350kg

- Sand: 430 - 450kg

- Water: 200 litres

- Lightweight concrete foaming agent: 0.65 - 0.7kg

* Cement or sand can be substituted with fly ash

Designed and installed by us to ensure maximum efficiency for your investment

The CLC brick manufacturing plant consists of equipments designed and manufactured by THT International such as light concrete mixer, block cutting machinhe, molds ... They are high in capacity, easy to use and maintain, and have long working life. This block plant can be designed completely automatic or semi-automatic depending on the requirements of our customers.

We can design, install and handover a complete CLC plant manufacturers in the form of turnkey projects.

Equipments needed for high capacity CLC brick manufacturing plant

MasterCut CLC block cutting machine

Allows you to simultaneously cut one concrete cake on 2 sides into small bricks

Lightweight concrete foaming agent

THTFA-3 foaming agent is a highly concentrated, highly efficient, low dosage liquid

Silo & Screw Conveyor

Use to store and transport raw material to the mixer

Scissor lift

Can be mounted on a forklift or crane, and make it easy to pick up bricks and put them onto pallets

Curing chamber

To cure bricks after cutting to make them dry & increase strength

Cellular Lightweight Concrete Production Line

We can design and install CLC block manufacturing plant with the capacity from 10 to 200m3/day

Cellular Lightweight Concrete Technology

We are one of the leading manufacturers of CLC foam concrete equipments, and have exported to many countries around the world. We can supply machines as part of a production line, or complete turn-key manufacturing plants.

Lightweight Concrete Equipments