Introduction, benefits and technical specifications of V-lite lightweight concrete panel

V-lite - Lightweight concrete panels

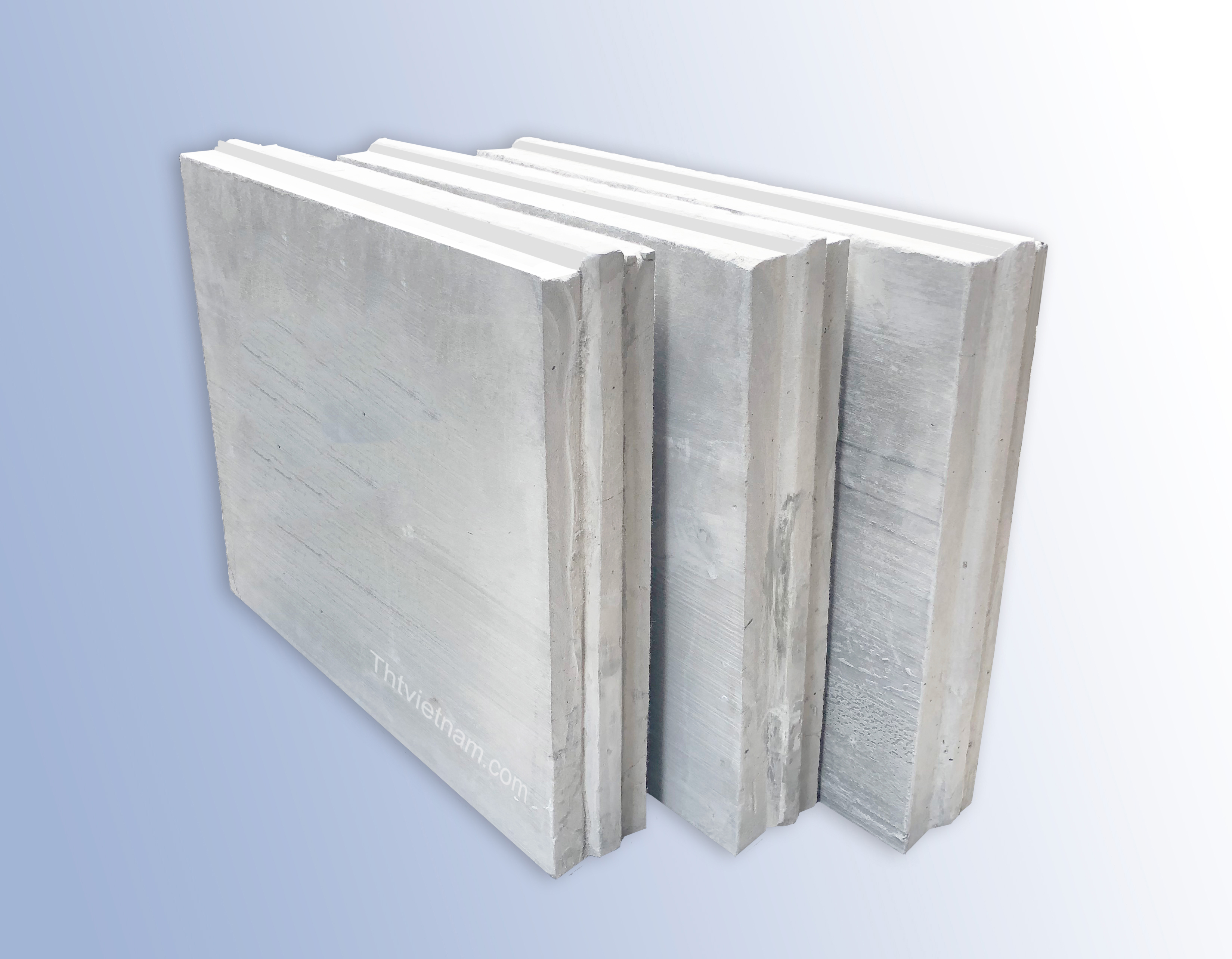

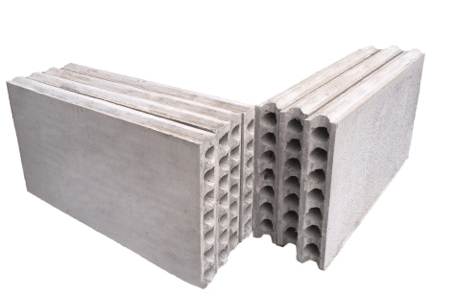

V-lite lightweight concrete wall panels are produced from foam concrete, with additives and synthetic fibers.

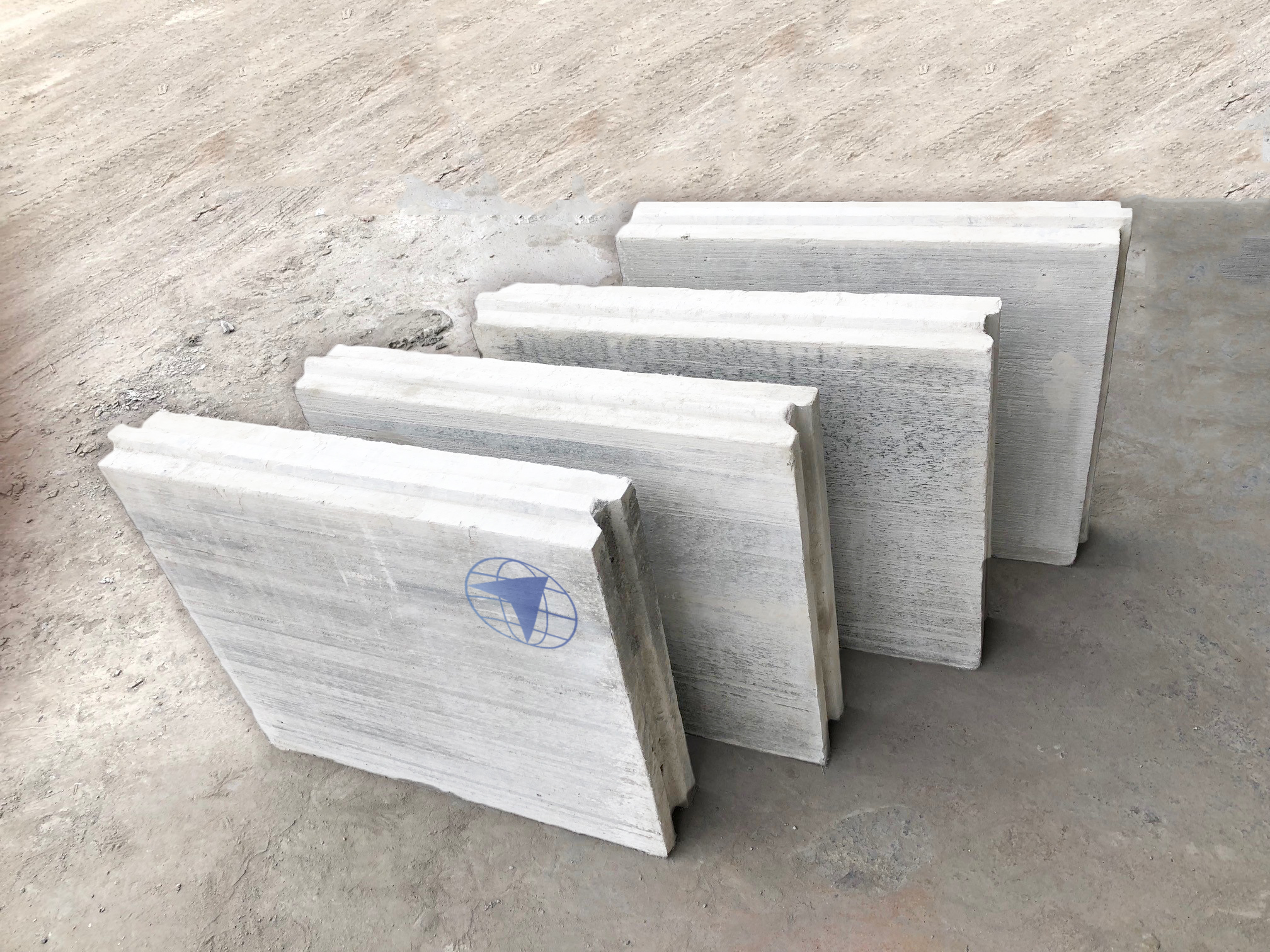

The V-lite panels have tongues and grooves on 4 sides to allow easy and fast installation. Additionally, due to the reduced amount of mortar required, there will be less debris and dust during installation, hence eliminate the need for time-consuming cleaning works, and helps save the huge amount of labors for constructors.

These wall panels have excellent physical properties: high heat and sound insulation, waterproof, fireproof and lightweight, with high strength. The panels can be produced with steel grid reinforcement as an option to achieve higher mechanical properties and safety.

V-lite Panels now is a great choice for building walls, ceilings, and floors of buildings, offices, houses ..., reducing the time of construction, save costs and friendly to the environment.

Outstanding advantages of V-lite wall Panels

-

The speed of construction and labor-saving: 3 workers can build a wall of 15m2 in 1 hour.

-

Saving of mortar: the mortar needed for works is just 20-25% compared to using traditional brick and 40-50% compared to using AAC of CLC blocks.

-

Ease of installation: electric and communication cables, pipelines can be installed much easier, cheaper and faster.

-

Lower construction costs: the final cost to build 1m2 of a wall by V-lite concrete panels is 40-50% lower compared to clay bricks wall or 70-75% lower compared to AAC/CLC blocks wall. This brings an enormous saving and profit to the investor (not to mention the cost savings from early completion of the project and about 30% reduction of the foundation cost thanks to the light weight of the wall).

-

Energy savings: V-lite lightweight wall panels are suitable for high-rise buildings construction. It helps to save energy bill by reducing the cost of air conditioning, heating due to great heat & sound insulations.

-

Environment-friendly: this is an environmentally friendly product, encouraged by many countries in the efforts to protect the environment, eliminating the CO2 from clay bricks production which brings about climate change.

Main application:

-

V-lite panels are mainly used to build walls which are not load bearing. The lightweight concrete panels of 100mm thick are mainly for inner partition walls, while the lightweight concrete panels of 150/200mm thick are for outer surrounding walls. Higher density panel can be considered for load bearing at 1-2 floors houses.

-

V-lite panels are recommended for hospitals, schools, warehouses, industrial and commercial buildings, and especially recommended being used for apartments in high-rise buildings, affordable housing projects.

Lightweight Concrete panels with hollow-Core for partition walls construction

The V-lite lightweight wall panels have tongues and grooves at 4 sides to allow easy and fast installation

High speed of construction and saving of labor with lightweight concrete wall panels

Technical specifications:

| Sizes |

1200 x 500 x 100mm 1200 x 500 x 150mm 1200 x 400 x 100mm 1200 x 400 x 150mm |

| Weight | From 37 to 66kg/panel depending on panel size |

| Concrete strength (Minimum) | 3.5 to 5.0 N/mm2 |

| Density | 700 - 850 kg/m3 |

| Sound insulation | 60 to 70.5 dB |

| Water absorption | less 10% |

| Fireproof | more than 2 hours with a 150 mm thick panel |

| Certification | Meets UK Standard BS 5243 & TCVN 9020: 2017 |

Compare the time to build 1m2 wall with red brick and with lightweight concrete panel V-lite panel

| Comparison table of buiding time of 1m2 wall with V-lite panel (size 600x100x500) and with red brick (2 holes, size 220x105x60 mm) | ||||

| Comparative factors | Unit | Red brick | V-lite panel | |

| Dimension | Length | m | 0.22 | 0.6 |

| Wide | m | 0.105 | 0.1 | |

| High | m | 0.06 | 0.5 | |

| Mortar thickness | m | 0.012 | 0.004 | |

| Number of bricks needed to build 1m2 wall | block | Needed bricks = 1m2/((high+mortar thickness) x length) | ||

| 63.13 | 3.31 | |||

| Faster building time than red brick | x time | faster time (estimate) = 63.13 / 3.31 * | ||

| 19.09 | ||||

* This time of construction does not include the time of plastering mortar for each red brick and panel

Through this comparison table, it is clear that the building time of 1m2 wall with precast lightweight concrete panels will be nearly 20 times faster than the traditional red brick.

Saving time also means saving money, while the quality of the wall is much better with many features such as fire resistance, heat resistance, sound insulation ...

Because of these superior features, using lightweight concrete materials such as the V-lite panel is becoming a trend for the new era construction industry around the world.

In many country, the Government has also introduced incentives for using lightweight concrete materials in some type of construction projects, which has opened a new direction for construction materials manufacturers.

If you are intending to build a contruction materials plant or you want to improve your old production line to keep up with the trends, you can learn more about our lightweight foam concrete production plant and technology

Building a wall with lightweight concrete panel video

The V-lite lightweight concrete wall panel is not only easy and fast to build but it also gives you a hight quality wall. The construction steps as well as quality testing of the lightweight concrete panel wall are shown in the video beside

Cellular Lightweight Concrete Technology

We are one of the leading manufacturers of CLC foam concrete equipments, and have exported to many countries around the world. We can supply machines as part of a production line, or complete turn-key manufacturing plants.

Lightweight Concrete Equipments

Share your project details with us, and we'll ensure the right team member gets back to you promptly.